Description

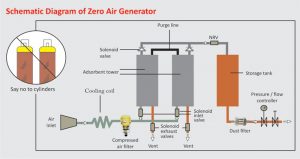

• Zero Air Generator produces a continuous flow of high purity Zero Air at selected pressure.

• The modular pressure swing adsorption (PSA) unit operates with alternating pressure increase and decrease.

• Untreated air flows under pressure through the reaction towers containing molecular sieve adsorber.

• Moisture, CO, CO2, THC and other unwanted components in the air are adsorbed, leaving Zero Air Gas of required purity.

• The Zero Air Generators are suitable for use in laboratories and industrial environments.

• Microcontroller digital display

Technical Specification

| PRINCIPLE SPECIFICATIONS | ZAG-02 (for 2-5 GC’s) (for Imported GC) |

| Moisture | < 2 ppm |

| Total Hydro Carbon | < 0.5 ppm |

| CO & CO2 | < 2 ppm |

| Purity | GC/UHP grade |

| Micro Particulates | < 0.01µ |

| Capacity of ZAG | 4 LPM at 5kg/cm² |

| Method of purification | Pressure Swing Adsorption (PSA) |

| Room temperature | 5 °C – 25 °C |

| Start up time | 5 minutes |

| Electrical requirements for ZAG | 230 VAC, 50 Hz, 1 ph, 4 Amp |

| Size of ZAG without compressor (in mm) | 600H x 400W x 350D |

| Net weight of ZAG w/o compressor | 35 kg. |

| Power Consumption | 250 W |

Salient Features:

• Deliver constant pressure & flow

• Fully Automatic Programmable System

• Easy Maintenance and space saving

• Effortless and easy operation

• Improves instrument performance

• Fully regenerative, durability with PSA technology

Applications:

• GC-FID, FPD, NPD, TCD, AED

• GC-MS, LC-MS-MS, ICP / NMR

• FTIR / IR, ELSD detector

• Purging, Ampule Filling

• Thermal instruments, Turbo Evaporator (N2 Concentrator)

• All Analytical Instruments

Note:

• Zero Air Generator (Model ZAG-02) requires oil free compressed air line of 60 LPM at 6 kg/cm²

• Oil free compressor can be provided by PCI.

• For model ZAG-03, PCI oil free compressor is recommended

Reviews

There are no reviews yet.